Ukuma kwezinhlayiya ze-superabrasive kanye nokwakheka kwe-coating kudlala indima ebalulekile ekufanelekeni kwamasondo okugaya izinhlelo zokusebenza ezihlukahlukene.

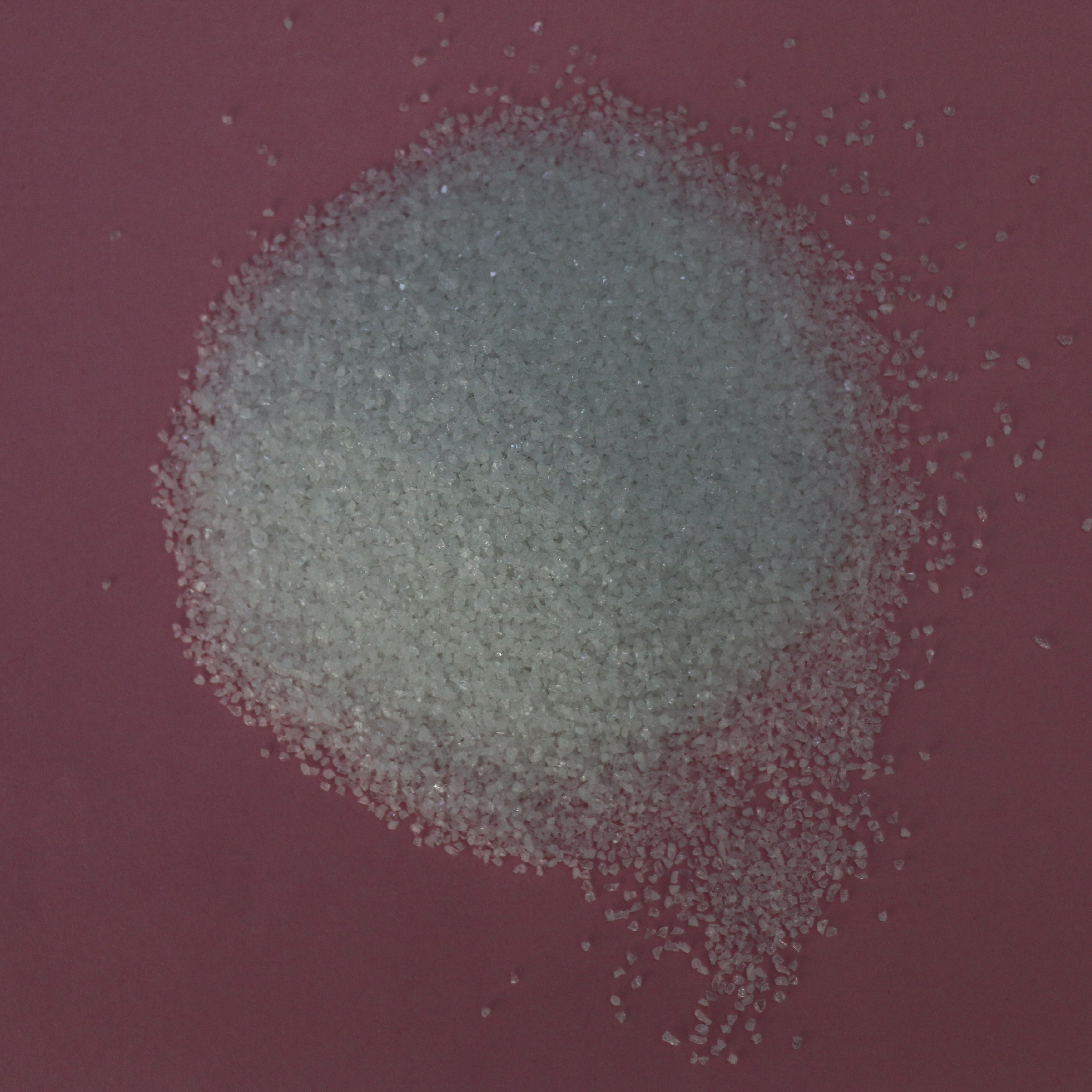

Ukufanisa uhlelo lokusebenza nesondo elingcono kakhulu le-superabrasive kungazuza ngokuthuthukisa ingxenye yekhwalithi kanye nesivuno somkhiqizo, ukwenza ulwazi olujulile lwe-grit, ibhondi kanye nezakhiwo zokumboza ezibaluleke kakhulu kubasebenzisi bomshini wokugaya.Isithombe sihlonishwa ngu-Wanyu Abrasives.

Ukukhetha okulungile kwamasondo okugaya aqinile kubalulekile ukuze kube nenqubo ephumelelayo yokugaya.Isondo elilungile lingathuthukisa izingxenye ngehora, linciphise izinguquko zamathuluzi, likhulise isikhathi somshini, lithuthukise ikhwalithi yomkhiqizo futhi lehlise izindleko zokusebenza.Kodwa-ke, ukuthola isondo elinjalo kudinga ukutadisha ngokucophelela ukuma okusanhlamvu kanye ne-superabrasive coating, phakathi kwezinye izici.

Amasondo okugaya ama-Superabrasive asebenza ngaphansi kwezimo ezinzima zokugaya futhi kufanele abe nenani lezinto, kufaka phakathi ubulukhuni emazingeni okushisa aphezulu, ukushisa okuphezulu kwe-thermal ukuze kususwe ukushisa onqenqemeni lokusika, ukuzinza kokwakheka, ukumelana nokugqoka, ukuthambisa kanye nokumelana nokuguqulwa kwepulasitiki.

Ukusebenza kwesondo lokugaya elinamandla amakhulu kunqunywa ngokuyinhloko i-substrate eboshiwe, kanye nezici zemvelo kanye nekhwalithi yohlamvu olubi lwesondo, kungaba idayimane noma i-cubic boron nitride (CBN).Izinhlayiya ezihlukene kanye nezingubo zokugqoka zinikeza amandla ahlukene futhi ngakho-ke zilungele izinhlelo zokusebenza ezahlukene.Ukwazi ukuthi yiziphi izinhlayiya nezingubo ezilungele izinhlelo zokusebenza ezithile kungasindisa imali yabakhiqizi ngokuhamba kwesikhathi.

Kuye ngesicelo noma inqubo yokugaya, okusanhlamvu kweprimiyamu noma okusanhlamvu okumba eqolo kungase kube inketho yokonga kakhulu emsebenzini.Ngokufanayo, amasondo edayimane abiza kakhulu noma e-CBN angase angalufanele uhlelo olunikeziwe.Okubalulekile akuyona intengo, kodwa ukuma kwezinhlamvu ze-superabrasive kanye nohlobo lokumboza olusetshenziswa esondweni.

Ukuqina kubhekisela ekuziphatheni kwezinhlamvu ezilumayo ngaphansi kwengcindezi yemishini, okungukuthi, ikhono layo lokumelana nokuqhekeka, ukuqhekeka, nokuphuka.I-Brittleness ibhekisela ekhonweni lokusanhlamvu lokuphuka nokuzilola.

Izinhlamvu eziqine kakhulu ezihuqayo zivame ukuba maqina futhi zibambe umumo wazo kangcono kunokuba zisuse izinto.Ama-brittle particles alolwa ngezikhathi ezithile, ukuma kwawo kwe-angular kususa izinto eziningi ngephasi ngayinye.Ukufakwa okuhlukile kudinga okusanhlamvu ezindaweni ezihlukene ku-spectrum phakathi kwalezi zinhlobo ezimbili.

Ngokwefomu, kunezigaba ezimbili ze-polar: i-blocky ne-angular.Uma izinhlayiya eziqhumayo zihlangene kakhulu noma ziyindilinga, ukusika kuyancipha, kodwa ukwakheka kugcinwa kangcono.Izinhlayiya ezihlangene zinamandla futhi zimelana namandla abrasive aphezulu ngaphambi kokuphuka.

Ngokuphambene, izimo ze-angular zinolaka futhi zingena kangcono futhi zisuse izinto ezibonakalayo.Nokho, okusanhlamvu angular kubhujiswa ngomzamo omncane.

Okufanelekile, kufanele kube nezinhlayiyana ezilinganisa lezi zimo ezimbili, ezivumela ukuthi zihlale ziqinile, zivumela ukuba zihlehle ngokwemvelo, ziveze umphetho omusha, obukhali wokusika.Ngaphandle kwekhono lokuhlakazeka, okusanhlamvu kuzoba buthuntu futhi kuhlikihle kucezu lokusebenza esikhundleni sokusika, kubangele ukwanda kwamandla okugaya kanye nezinkinga ezinkulu zesondo nomsebenzi.

Ukugqoka kuyinqubo yokuhlanganisa ngokuphelele futhi ngokulinganayo okusanhlamvu kwe-superabrasive ngesendlalelo sezinto ezengeziwe.Le nqubo ikhulisa usayizi wokusanhlamvu nesisindo, okuvame ukusetshenziselwa ukuthuthukisa izimfanelo ezifana namandla nokuqina ekugayeni.

Amandla e-matrix eboshiwe ukuze abambe uhlamvu olubi anquma ukusebenza kahle kwesondo lokugaya.Inzuzo eyinhloko yezingubo zokugqoka ukuthi zingakwazi ukuthungatha izinhlayiya zedayimane noma ze-CBN ukuze zinamathele kangcono esondweni, kungaba yi-resin, vitreous, metal, hybrid noma enye.Ukugcinwa okuthuthukisiwe komshini namakhemikhali wesistimu yokubopha kuthuthukisa ubuqotho besondo.

Ukonga izindleko kanye nokukhiqiza okuphezulu okuza nokukhetha isondo elifanele lokugaya kalula kungaba inzuzo yokuncintisana uma iworkshop idlala amakhadi ayo kahle.

I-Nickel, i-copper ne-silver coatings yizimbozo ezivame kakhulu ze-superabrasive.Ukufakwa kwe-nickel kuvamile kumasondo ahlanganiswe ne-resin.Lezi zimbotshana zithuthukisa impilo yamasondo, ukuphela kwendawo, ukunqanyulwa kokushisa nokunamathela ngomshini ezindaweni ezibophayo ukuze kwandiswe ukusebenza.

Izembatho zethusi ziyi-coating yokuzikhethela ukugaya okomile ngenxa yekhono lethusi ukuqhuba ukushisa kude nendawo yokugaya futhi kuthuthukise ukugcinwa kwezinhlayiya zemishini kanye namakhemikhali ohlelweni oluboshiwe.

Izingubo zesiliva zibiza kakhulu kodwa zinikeza ukuqhutshwa kokushisa okuphezulu kakhulu kwezinhlobo ezintathu zokumboza, kanye nokugcinwa kwezinhlayiyana okuthuthukisiwe kanye nokuthambisa okwengeziwe.Isiliva ukuphela okuthandwayo lapho uwoyela omsulwa usetshenziswa njengesibambiso.

Inani lokumboza kokusanhlamvu okuhuquzelayo lingaba kusuka ku-30% kuya ku-70% wesisindo esiphelele sokusanhlamvu okuboshiwe.Izembatho ezinhlayiyeni zedayimane ngokuvamile zingu-50% kuya ku-56% ngesisindo, kuyilapho izinhlayiya ze-CBN zivame ukusetshenziselwa ukumboza ngo-60% ngesisindo.Ama-superabrasives agqinsiwe avame ukubiza kakhulu kune-abrasives engagcotshiwe ngenxa yokusebenza kwawo okuphezulu okulindelekile kanye nezinyathelo zokukhiqiza ezengeziwe ezidingekayo ukuze azikhiqize.

Ngisho nokulungiswa okuncane ku-abrasive kusondo lokugaya kungaba uguquko lwegeyimu kusistimu yakho yokugaya nenqubo.Ukonga izindleko kanye nenzuzo yokukhiqiza ngokukhetha isondo elifanele lokugaya kalula kungaba inzuzo yokuncintisana uma iworkshop idlala amakhadi ayo ngendlela efanele.

Ngokusebenzisa amasu okugaya asezingeni eliphezulu, asebenza kahle kakhulu ohlelweni lomshini, ubuchwepheshe be-SolidCAM iMachining bunganciphisa kakhulu izikhathi zomjikelezo futhi bukhulise kakhulu impilo yamathuluzi uma kuqhathaniswa nokugaya okuvamile.

Amandla ahilelekile ohlelweni lokugaya angalinganiswa, okuvumela amathuluzi ezibalo ukuthi asetshenziselwe ukubikezela nokulawula lawa mandla.Amafomula anembile okubala lawa mandla akuvumela ukuthi uthuthukise ikhwalithi yomsebenzi wokugaya.

Isikhathi sokuthumela: Apr-23-2023