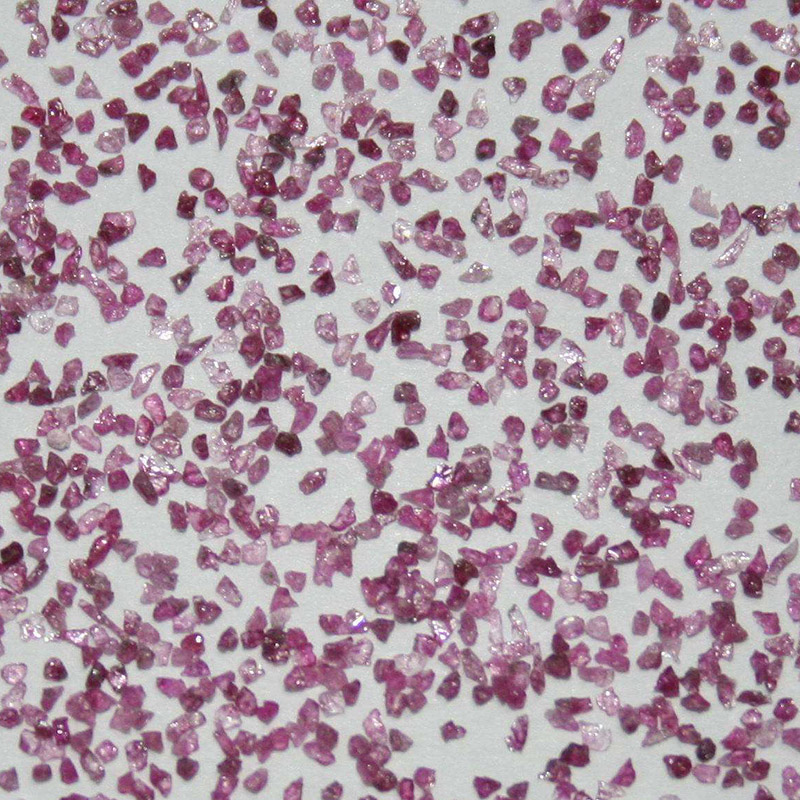

I-Chrome corundum (eyaziwa nangokuthi i-pink corundum) yenziwa ukusabela kwamakhemikhali kwe-metallurgical chrome-green kanye ne-alumina yezimboni ezingeni lokushisa eliphezulu elingaphezu kwama-degree angu-2000.Inani elithile le-chromium oxide liyengezwa phakathi nenqubo yokuncibilika, okunsomi ngokukhanyayo noma i-rose.

I-Chromium corundum ihamba phambili ekusebenzeni okuphelele okuhlanganisa ubulukhuni obuphezulu, ukuqina okuphezulu, ukuhlanzeka okuphezulu, ukuzilola okuhle kakhulu, ikhono eliqinile lokugaya, ukukhiqiza ukushisa okuphansi, ukusebenza kahle okuphezulu, ukumelana ne-asidi ne-alkali, ukumelana nezinga lokushisa eliphezulu, nokuzinza okuhle kokushisa.

Ukwengezwa kwento yamakhemikhali u-Cr ku-chrome corundum kuthuthukisa ukuqina kwamathuluzi ayo abrasive.Ifana ne-white corundum ngobulukhuni kodwa iphakeme ngokuqina.Amathuluzi abrasive enziwe nge-chrome corundum anokuqina okuhle nokuqeda okuphezulu.Isetshenziswa kabanzi ku-abrading, ukugaya, ukupholisha, ukuphonsa isihlabathi ngokunembile, izinto zokufafaza, umthwali we-catalyst wamakhemikhali, izitsha zobumba ezikhethekile nokunye.Izinkambu ezisebenzayo zifaka: amathuluzi okulinganisa, izinsimbi zokuphotha zethuluzi lomshini, izingxenye zamathuluzi, ukugaya okunembayo ekukhiqizweni okunentambo kanye nemodeli.

I-chrome corundum ine-viscosity ephezulu kanye nokungena kahle ngenxa yengxenye yengilazi equkethe i-chromium oxide, engavimbela kakhulu ukuguguleka nokungena kwe-slag encibilikisiwe.Ibuye isetshenziswe kabanzi ezindaweni zokushisa eziphakeme ezinemvelo enokhahlo, okuhlanganisa iziko le-metallurgy ezingezona ayoni, izindawo zokuncibilikisa ingilazi, ama-carbon black reactors, izishisi zikadoti kanye nezinto ezilahlwayo eziphikisayo.

Imikhiqizo ye-Chromium corundum

Izinkomba zomzimba namakhemikhali

| Okuqukethwe kwe-Chromium oxide | I-chrome ephansi 0.2 --0.45 | I-chromium 0.45--1.0 | I-chromium ephezulu 1.0--2.0 |

Ibanga lobumbudumbudu

| I-AL2O3 | Na2O | Fe2O3 | |

| F12--F80 | 98.20 min | 0.50 ubuningi | 0.08 ubuningi |

| F90--F150 | 98.50 imiz | 0.55 ubuningi | 0.08 ubuningi |

| F180--F220 | 98.00 imiz | 0.60 ubuningi | 0.08 ubuningi |

Ukuminyana kwangempela: 3.90g/cm3 Ukuminyana ngobuningi: 1.40-1.91g/cm3

Ubulukhuni obuncane: 2200-2300g/mm2

I-Chrome Corundum Macro

| I-PEPA | Isilinganiso sikasayizi wokusanhlamvu(μm) |

| F 020 | 850 - 1180 |

| F 022 | 710 - 1000 |

| f024 | 600 - 850 |

| F 030 | 500 - 710 |

| f036 | 425 – 600 |

| f040 | 355 - 500 |

| f046 | 300 - 425 |

| f054 | 250 - 355 |

| f060 | 212 – 300 |

| f070 | 180-250 |

| f080 | 150 - 212 |

| f090 | 125 – 180 |

| F 100 | 106-150 |

| F 120 | 90 – 125 |

| F 150 | 63-106 |

| F 180 | 53-90 |

| F 220 | 45-75 |

| F240 | 28-34 |

Ukuhlaziya ngokomzimba okujwayelekile

| I-Al2O3 | 99.50% |

| I-Cr2O3 | 0.15 % |

| Na2O | 0.15 % |

| Fe2O3 | 0.05 % |

| I-CaO | 0.05 % |

Izici ezibonakalayo ezijwayelekile

| Ukuqina | 9.0 awu |

| Color | pink |

| Isimo sokusanhlamvu | i-angular |

| Iphoyinti lokuncibilika | ca.2250 °C |

| Izinga lokushisa eliphezulu lesevisi | ca.1900 °C |

| Amandla adonsela phansi athize | ca.3.9 – 4.1 g/cm3 |

| Ukuminyana ngobuningi | ca.1.3 – 2.0 g/cm3 |