Imikhiqizo ye-Chromium Corundum Refractory

incazelo yomkhiqizo

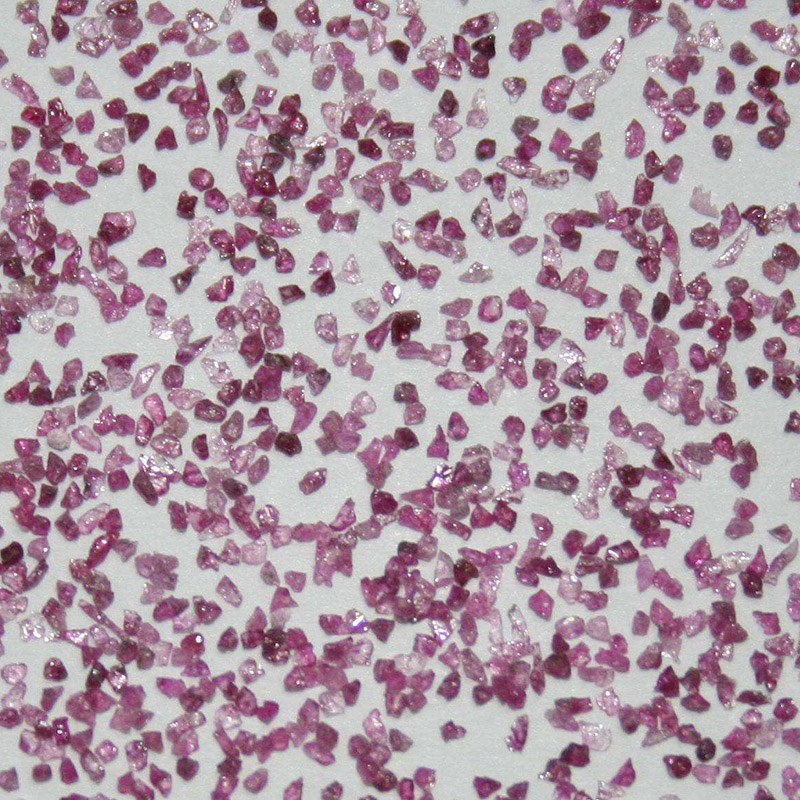

Izinto ezingavuthiwe ezisetshenziswa emikhiqizweni yochungechunge lwe-chromium corundum yisixazululo esiqinile esihlanganiswe ukuncibilika kwezinga lokushisa eliphezulu kwe-alumina ne-chromium oxide ngengxenye ethile.Impahla eluhlaza eyinhloko i-bauxite ephezulu (noma i-alumina yezimboni) ngokwengeza inani elifanele le-chromite nokulinciphisa.I-ejenti iyancibilika ekushiseni okuphezulu esithandweni sikagesi, bese i-chromium encibilikisiwe ithululelwa esibunjeni ukuze ipholiswe kancane, bese yenziwa ngemva kokuhushulwa..

Imikhiqizo ye-Chromium corundum refractory ehlanganisiwe ye-chrnmecorundum refrac-tory ibizwa nangokuthi i-fused cast chrnmecorundum refrac-tory.Umkhiqizo ohlanganisiwe we-refractory owenziwe ngesisombululo esiqinile se-alumina ne-chromium oxide kanye nenani elincane le-spinel, eliqukethe u-60% kuya ku-87% we-alumina kanye no-30% we-chromium oxide.Ukuminyana kwenqwaba kungu-3.2-3.9g/cm3;, amandla okushisa aphezulu aphezulu, uma kuqhathaniswa nezinye izinhlobo ze-corundum refractories, ukumelana nokugqwala kwe-glass melt kunamandla kakhulu.Ingasetshenziswa njengolwelwesi lweziko oluthintana ngqo nengilazi encibilikisiwe.

I-Chromium corundum refractories isetshenziswa kakhulu olwelweni lwegesi yamalahle e-slurry pressurized gasifier, ladle refining furnace kanye ne-carbon black reactor lining, imboni ye-petrochemical imboni ye-slag gasification ulayini wesithando somlilo kanye nengilazi encibilika isithando somlilo, njll., futhi ingasetshenziselwa ukufudumeza I-chrome Isitini seplatifomu ye-corundum yesithando somlilo siyinto ebaluleke kakhulu embonini yokushisa okuphezulu.

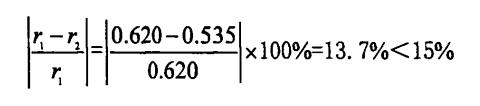

I-AL203 ne-Cr2O3 ingeyesakhiwo se-corundum, irediyasi ye-Cr3+ ingu-0.620, kanti irediyasi ye-AL3+ ingu-0.535.Ngokusho kwefomula ye-empirical:

Njengoba umehluko phakathi kwe-Cr3+ ne-AL3+ ion radii ungaphansi kuka-15%, ama-Cr ions angashintsha ngokuqhubekayo nangokungenamkhawulo esikhundleni se-AL ku-AL203 lattice, enze isixazululo esiqinile esiqhubekayo esingenasiphelo.

Isakhiwo sekristalu se-Cr203 ne-AL203 ziyefana, futhi i-ionic radius ihluka ngo-13.7%.Ngakho-ke, i-Cr203 ne-AL203 zingakha isixazululo esiqinile esingapheli ezingeni lokushisa eliphezulu.Ngokombono womugqa wesigaba soketshezi oluqinile, ngokukhuphuka kokuqukethwe kwe-Cr203, izinga lokushisa lapho isigaba soketshezi siqala ukubonakala nalo liyakhuphuka.Ngakho-ke, ukungeza inani elifanele le-Cr203 ku-AL203 kungathuthukisa kakhulu izakhiwo zemishini kanye nokusebenza kwesevisi yezinga eliphezulu lokushisa kwama-corundum refractories.

I-Cr203 ingenza indawo ephezulu yokuncibilika noma i-eutectic enezinga lokushisa eliphakeme lokuncibilika elinama-oxide amaningi avamile.Isibonelo, i-FeO·Cr203 spinel ekhiqizwe i-Cr203 futhi i-Feo inendawo yokuncibilika efinyelela ku-2100℃;I-Cr203 ne-AL203 zingakha isixazululo esiqinile esiqhubekayo.Ngaphezu kwalokho, i-Cr203 ingaphinda ikhulise kakhulu i-viscosity ye-slag futhi inciphise ukugeleza kwe-slag, ngaleyo ndlela yehlise ukugqwala kwe-slag ku-refractory.Ngakho-ke, ukwengeza inani elifanele le-Cr203 kokokusebenza okuyizibazi kunganciphisa kakhulu ukuchitheka kwesakhiwo kolayini lwesithando somlilo okubangelwa ukuguguleka kwe-slag.Akukho ukujwayela okusobala phakathi kwekhono lokugqwala le-slag kuya ku-chromium corundum refractories kanye nokuyisisekelo kwe-slag.

Isitini se-chromium corundum esenziwe ngezinto eziphikisayo ze-chromium corundum sisezithandweni.Lapho isisekelo se-slag singu-2, isitini se-chromium corundum sinokumelana okungcono kakhulu nokugqwala kwe-iron slag;lapho isisekelo se-slag singu-0.2, ukugqwala kwe-slag yethusi kuya kusitini se-chromium corundum Okuncane kakhulu;lapho isisekelo se-slag singu-0.35, ukugqwala kwe-tin slag kusitini se-chrome corundum kuncane kakhulu;lapho isisekelo se-lead slag singu-0.3, ubukhulu bensalela bukhulu kakhulu futhi ukujula kongqimba lokusabela, ungqimba lokuguguleka kanye nongqimba lokungena luncane kakhulu.Uma i-slag alkalinity ingu-0.37, ukumelana nokugqwala kwezitini ze-chrome corundum kungcono kakhulu.