1. Yini i-refractory?

Izinto eziphikisayo ngokuvamile zibhekisela ezintweni ezingaphili ezingezona ezensimbi ezinokumelana nomlilo okungaphezu kuka-1580 ℃.Kubandakanya ama-ore emvelo kanye nemikhiqizo ehlukahlukene eyenziwe ngezinqubo ezithile ngokuya ngezidingo zenjongo ethile.Inezici ezithile zemishini yezinga eliphezulu lokushisa kanye nokuzinza kwevolumu enhle.Kuyinto edingekayo yazo zonke izinhlobo zemishini yokushisa ephezulu.Inezinhlobonhlobo zokusetshenziswa.

2. Izinhlobo zama-refractories

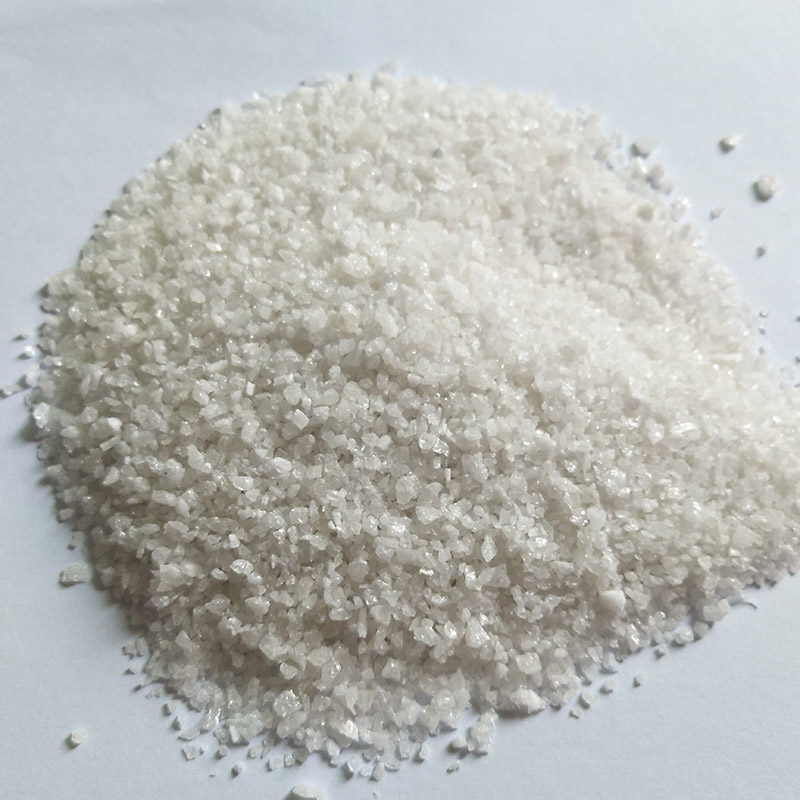

1. Ama-Refractories e-Acid ngokuvamile abhekisela kuma-refractories anokuqukethwe kwe-SiO2 okukhulu kuno-93%.Isici saso esiyinhloko ukuthi singakwazi ukumelana nokuguguleka kwe-acid slag ekushiseni okuphezulu, kodwa kulula ukusabela nge-alkaline slag.Izitini ze-silica nezitini zobumba zivame ukusetshenziswa njenge-acid refractories.Isitini se-silica siwumkhiqizo we-siliceous oqukethe ngaphezu kuka-93% we-silicon oxide.Izinto zokusetshenziswa ezisetshenziswayo zihlanganisa i-silica kanye nezitini ze-silica ezilahlwayo.Inokumelana okuqinile nokuguguleka kwe-acid slag, izinga lokushisa eliphezulu lokuthambisa umthwalo, futhi ayinciphisi noma ikhulise kancane ngemva kokubala okuphindaphindiwe;Kodwa-ke, kulula ukuguguleka nge-alkaline slag futhi inokumelana nokudlidliza okushisayo okushisayo.Isitini se-silica sisetshenziswa kakhulu kuhhavini we-coke, isithando somlilo sengilazi, isithando somlilo esine-asidi nezinye izinto ezishisayo.Isitini sobumba sithatha ubumba oluphikisayo njengento eluhlaza eyinhloko futhi iqukethe u-30% ~ 46% we-alumina.Kuyi-refractory ene-asidi ebuthakathaka enokumelana okuhle nokudlidliza okushisayo kanye nokumelana nokugqwala kwe-acidic slag.Isetshenziswa kabanzi.

2. Ama-alkaline refractories ngokuvamile abhekisela ezintweni eziphikisayo ezine-magnesium oxide noma i-magnesium oxide ne-calcium oxide njengezingxenye eziyinhloko.Lawa ma-refractories ane-refractoriness ephezulu kanye nokumelana okuqinile ne-alkaline slag.Isibonelo, isitini se-magnesia, isitini se-chrome se-magnesia, isitini se-chrome magnesia, isitini se-aluminium magnesia, isitini se-dolomite, isitini se-forsterite, njll. Isetshenziswa kakhulu esithandweni sokwenza insimbi ene-alkali, isithando somlilo esincibilikisa insimbi esingeyona ayoni kanye nesithando sosimende.

3. Ama-aluminium silicate refractories abhekisela kuma-refractories ane-SiO2-Al2O3 njengengxenye eyinhloko.Ngokusho kokuqukethwe kwe-Al2O3, zingahlukaniswa zibe i-semi siliceous (Al2O3 15 ~ 30%), i-clayey (Al2O3 30 ~ 48%) kanye ne-alumina ephezulu (i-Al2O3 enkulu kuno-48%).

4. Ukuncibilika kanye ne-casting refractory ibhekisela emikhiqizweni ephikisayo enomumo othize ngemva kokuncibilikisa inqwaba ekushiseni okuphezulu ngendlela ethile.

5. Ama-refractory angathathi hlangothi abhekisela kuzinzayo okungelula ukusabela kuzo nge-acidic noma i-alkaline slag ezingeni lokushisa eliphezulu, njenge-carbon refractories kanye ne-chromium refractories.Abanye baphinde bathi ama-alumina refractories aphezulu kulesi sigaba.

6. Ama-Special Refractory yizinto ezintsha ezingezona ezensimbi ezenziwe ngesisekelo sezitsha zobumba zendabuko kanye nezinsimbi ezijwayelekile.

7. I-Amorphous refractory iyinhlanganisela eyakhiwe nge-refractory aggregate, impushana, i-binder noma ezinye izixube ngesilinganiso esithile, ezingasetshenziswa ngokuqondile noma ngemva kokulungiswa koketshezi olufanele.I-refractory engakhiwe uhlobo olusha lwe-refractory ngaphandle kokubala, futhi ukumelana kwayo nomlilo akukho ngaphansi kuka-1580 ℃.

3. Yiziphi izinqamuleli ezisetshenziswa njalo?

Ama-refractories avamile avame ukusetshenziswa afaka isitini se-silica, isitini se-silica semi, isitini sobumba, isitini esiphezulu se-alumina, isitini se-magnesia, njll.

Izinto ezikhethekile ezivame ukusetshenziswa zifaka isitini se-AZS, isitini se-corundum, isitini se-magnesium chromium esiboshelwe ngokuqondile, isitini se-silicon carbide, isitini se-silicon nitride esiboshwe nge-silicon carbide, i-nitride, i-silicide, i-sulfide, i-boride, i-carbide nezinye i-non oxide refractories;I-calcium oxide, i-chromium oxide, i-alumina, i-magnesium oxide, i-beryllium oxide nezinye izinto eziphikisayo.

Izinto ezisetshenziswa kaningi ezishisayo ezishisayo kanye nezinto eziphikisayo zihlanganisa imikhiqizo ye-diatomite, imikhiqizo ye-asbestos, ibhodi lokufaka ukushisa okushisayo, njll.

Izinto ezisetshenziswa kaningi ze-amorphous refractory zihlanganisa izinto zokulungisa isithando somlilo, izinto zokunqanda ukumelana nomlilo, izinto ezikhandwayo ezingashi, amapulasitiki angashi, udaka olungashi, izibhamu ezingashi, izinto ezisanhlamvu ezingashi, izimbobo ezingashi, umlilo omncane. -ama-castable angavimbeli, udaka lwesibhamu, ama-valve e-ceramic, njll.

4. Yiziphi izici ezibonakalayo zama-refractories?

Izakhiwo ezingokoqobo zama-refractories zihlanganisa izakhiwo zesakhiwo, izakhiwo ezishisayo, izakhiwo zemishini, izakhiwo zesevisi kanye nezakhiwo zokusebenza.

Izakhiwo zesakhiwo se-refractories zifaka i-porosity, ukuminyana kwenqwaba, ukumuncwa kwamanzi, ukungena komoya, ukusatshalaliswa kosayizi wezimbotshana, njll.

Izakhiwo ezishisayo zama-refractories zifaka i-thermal conductivity, i-thermal expansion coefficient, ukushisa okuqondile, umthamo wokushisa, ukuqhutshwa kwe-thermal, ukukhishwa kwe-thermal, njll.

Izici zomshini wama-refractories zifaka amandla acindezelayo, amandla aqinile, amandla okuguquguquka, amandla okugoqa, amandla okugunda, amandla omthelela, ukumelana nokugqoka, ukukhasa, amandla ebhondi, i-elastic modulus, njll.

Ukusebenza kwesevisi yama-refractories kufaka phakathi ukumelana nomlilo, izinga lokushisa lokuthambisa umthwalo, ukushintshwa komugqa wokushisa kabusha, ukumelana nokushaqeka okushisayo, ukumelana ne-slag, ukumelana ne-asidi, ukumelana ne-alkali, ukumelana ne-hydration, ukumelana nokuguguleka kwe-CO, ukuguquguquka, ukumelana ne-oxidation, njll.

Ukusebenza kwezinto eziphikisayo kufaka phakathi ukungaguquguquki, ukwehla, uketshezi, ipulasitiki, ukuhlangana, ukuqina, ukuhlangana, ukuqina, njll.

Isikhathi sokuthumela: Mar-15-2022